Industrias Ochoa facilities include 30,000 square meters in Ribarroja del Túria (Valencia), with 18,000 square meters built to meet the needs of its customers. The company has another plant in Querétaro, Mexico, with 6,500m2 built in a land of 30,000m2.

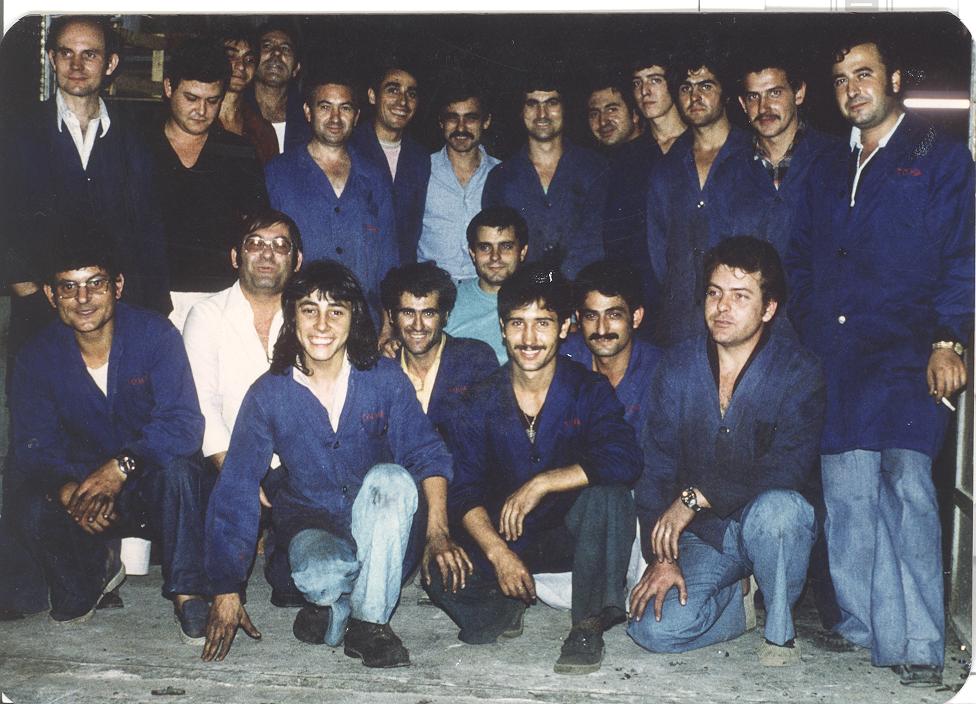

The company is created in a 72m2 workshop in Chirivella by brothers Domingo Ochoa and J.Miguel Castellanos plus two employees. The initial activity consists of machining and welding work per demand.

The activity is extended to the manufacture of molds, dies and tools, mainly for footwear fittings and ornaments.

The rapid company growth in surface until 1985 can be seen in the image.

The business is moved to the industrial area of Manises (opposite Valencia’s international airport), covering 1,000m2. New machinery is incorporated, production is expanded and size of the products is increased. The first important job for automotive is produced for Ford Fiesta; 60 million pieces would be manufactured within a period of 20 years..

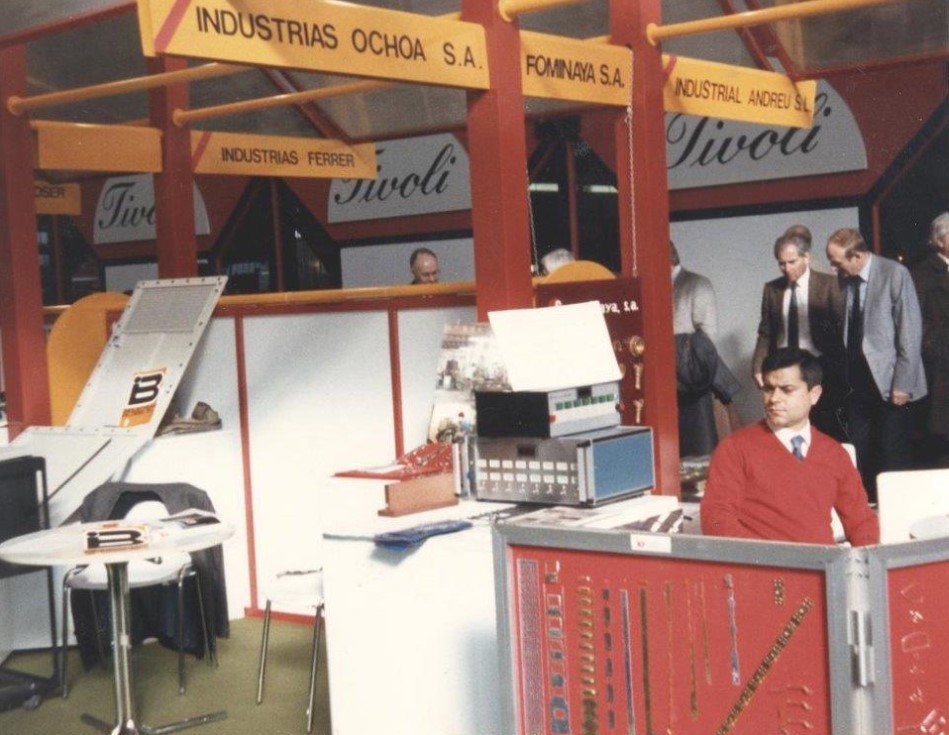

Expansion to 3,500 m2. It is the era of exporting through subcontracting trade missions. We definitely focus in the production of technical parts for automotive.

From the beginning, our working system is based in design, being pioneers in the use of Computer aided technologies (CAD-CAM).

At the same time, we participated in the first trainings for Quality Management done by Ford Valencia focusing in tools such as Statistical Process Control.

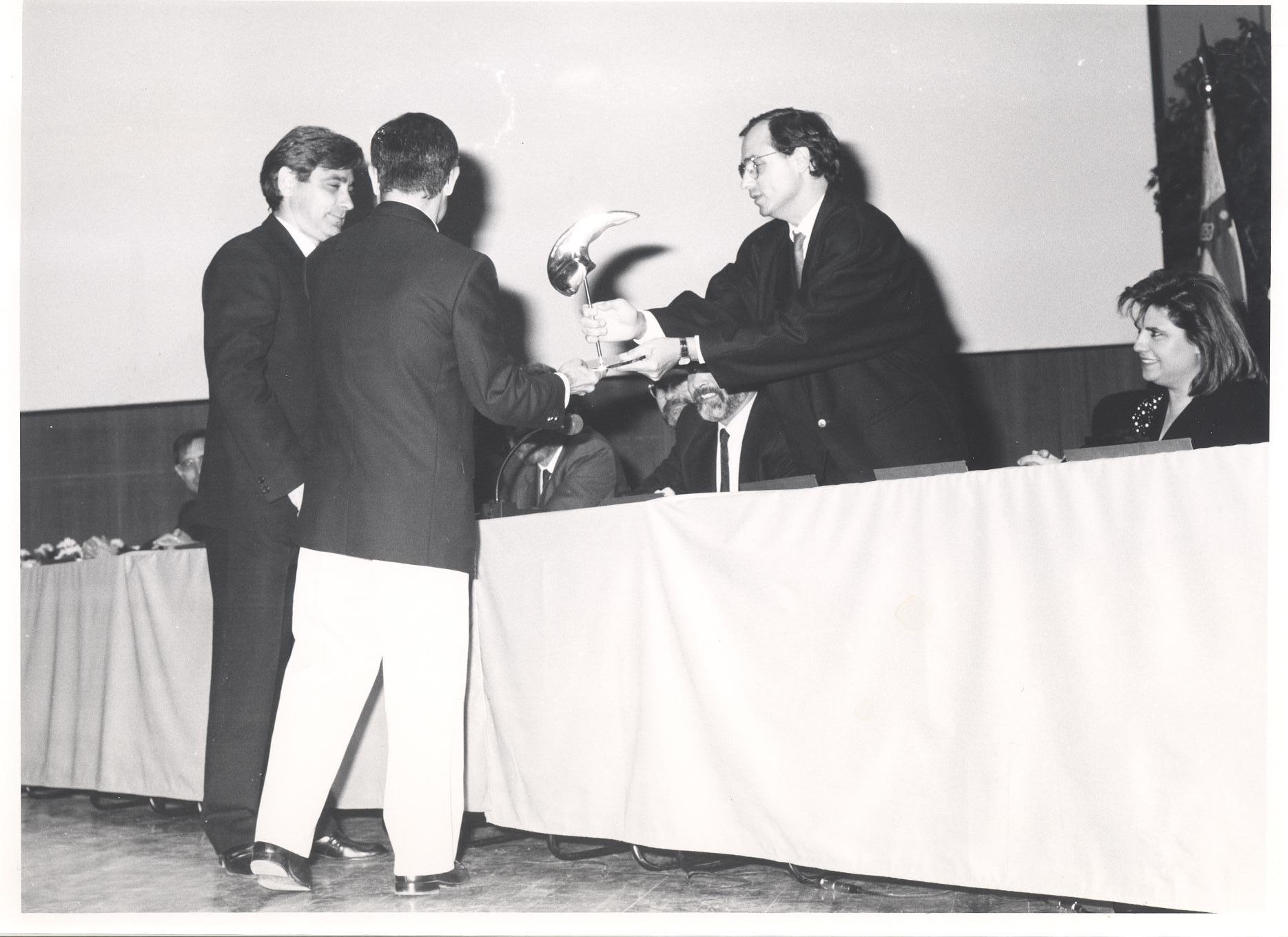

After 5 years of learning and deployment these new tools, we are the first company to receive the Quality and Innovation award from the Valencian Community. We Start using IT for production control.

We continue the growth with a new offices building and covering 5,000 m2. We occupy 12 different buildings within the industrial area, and exports exceed 70% of sales, figures that are still valid today.

The industry is moved to the current facilities in Ribarroja del Túria covering 10,000 m2 inside an area of 30,000 m2.

We work in R&D&i and we develop a 3D progressive dies design software.

The industry expands up to 14,000m2, incorporating new transfer presses and a robot tandem line, able to manufacture automobile doors. The company´s focus is now clearly in automotive.

The right moment for the decision of Internationalization, after the great crisis that had affected the whole society.

After several years looking for the place and developing the project, we decided to implement it in Mexico.

This year our commercial activity in this country begins.

Since 2009 we are working, first with the dies and tools, and then with the stamping and welding, to produce the Instrument Panel Carrier for the three cars made in Valencia, Ford C-MAX, KUGA and Transit. As a recognition for this program, FORD was awarding the Q1 in 2014.

The construction of the new plant in Querétaro is finished and mass production starts in September 2015.

This strategic internalization decision will bring large projects in Mexico and in Europe.

Award for the new FORD KUGA, this project involves the expansion and reorganization of the facilities up to 17,000m2.

Purchase of new AIDA transfer press with the latest generation of servo motor.

We are 50, thanks to our customers, suppliers and employees, who have allowed us to reach this milestone.